April 11, 2024

June 6, 2023

A look at the differences between natural and forced draft burners

What is the difference between natural and forced draft burners? Natural and forced draft burners differ in how they create airflow. They are used in several industrial applications that require the use of heat to achieve and utilize controlled combustion…

June 6, 2023

Lifespan of a Burner Management System and its related components

The lifespan of a burner management system and its related components are dependent on a number of factors including its use, environment, and maintenance schedule. Profire’s burner management systems are used in many industries where the overall efficiency, reliability, and…

June 6, 2023

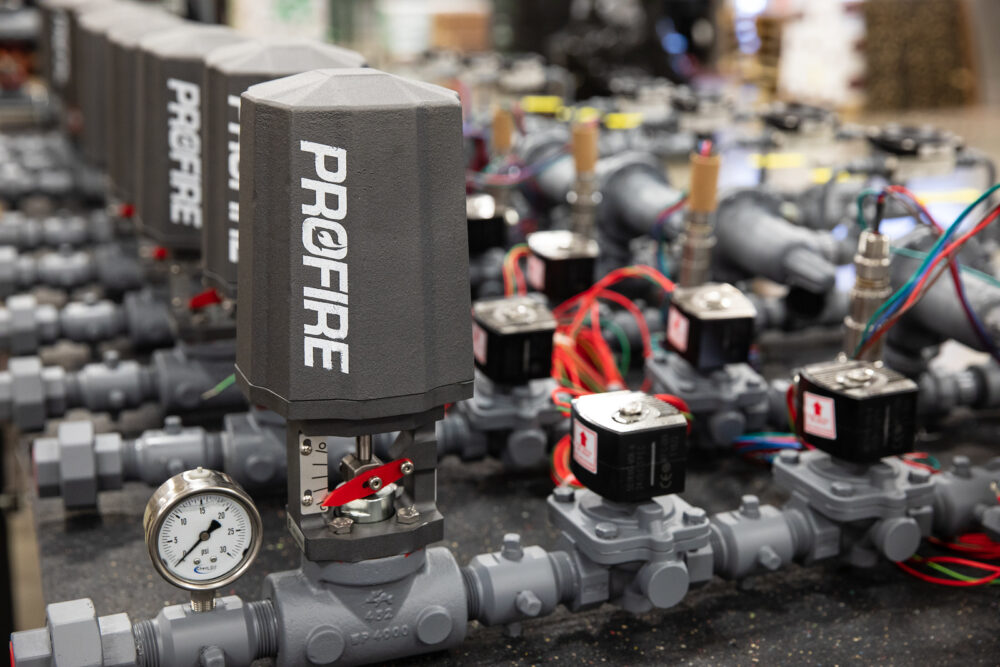

Fuel Train Configuration Factors

Fuel trains are integral for controlling the proper flow of gas into your natural or forced draft burner as part of your complete combustion control system. Each fuel train is customized with specific components to meet your application requirements and…