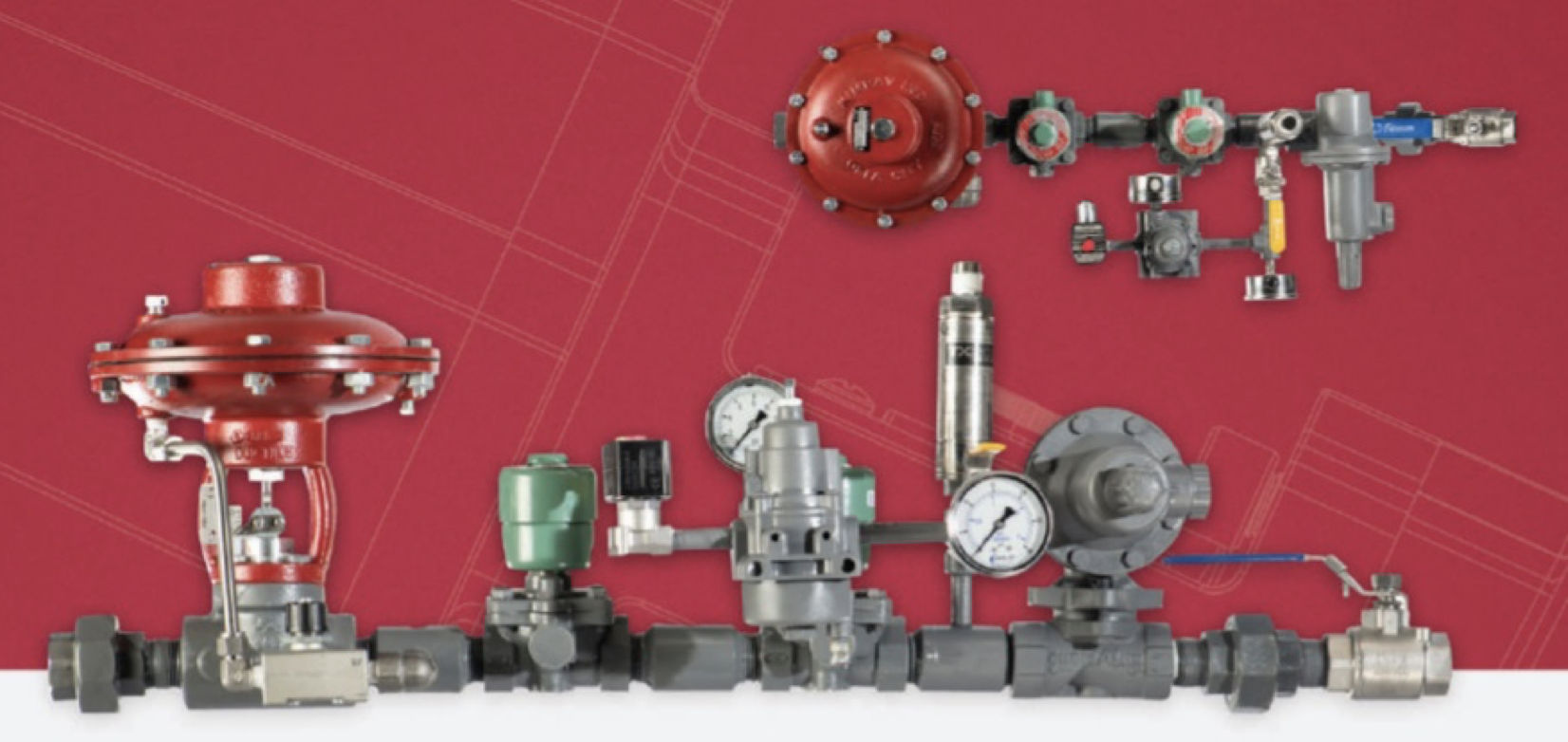

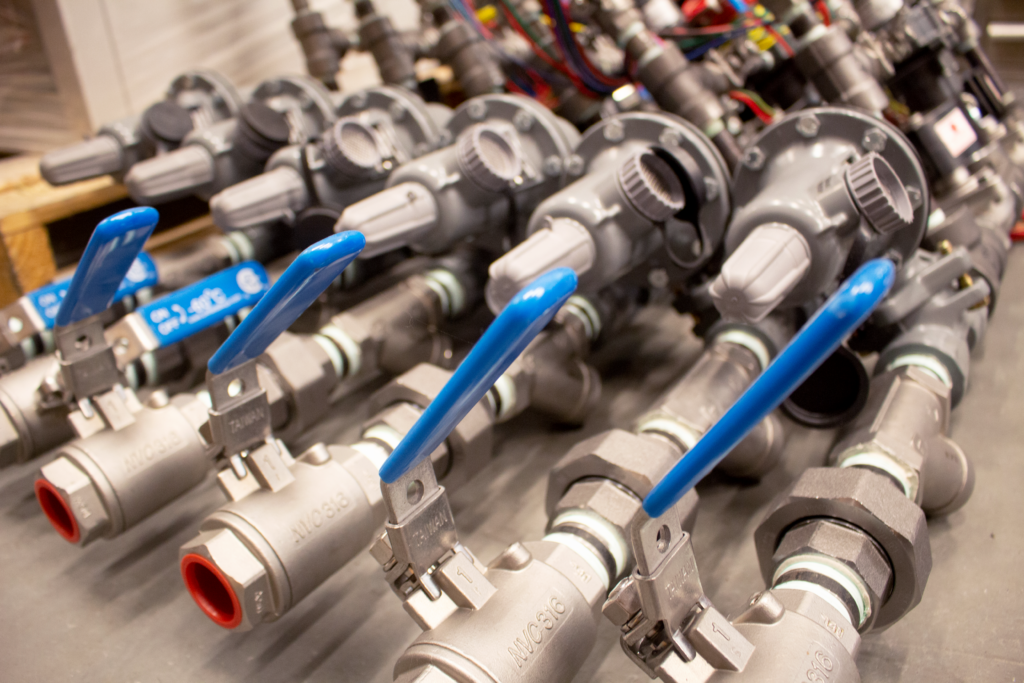

Essentially the heart of oil production or gas process treatment is the fuel train or sometimes referred to as the gas train. This series of valves, regulators, and switches carry fuel to burners, ensuring controlled flow and pressure. They also keep gas out of the combustion chamber during cycling or shutdowns. Fuel trains are used for many heating appliances in the following industries:

- Oil and Gas

- Power Generation

- Mining

- BioTech

- Petrochemical and Refining

- Renewables

- Landfill

- Agriculture

- Municipal

- Food and Beverage

- Construction and Infrastructure

- Pulp and Paper

Safety is integral to fuel trains with a rating greater or equal to 12,500,000 BTU/hour or more and require double block and bleed valves for extra safety. Additional components are also required to ensure that safe light-offs and shutdowns occur immediately if any type of failure occurs during operation. Irregular fuel pressures in the fuel train will also trip fuel pressure switches and cause the unit to shutdown. Switches are also used to ensure airflow is correct for purging residual combustibles prior to light-off.

Profire offers a number of pre-built and customizable fuel train options to ensure optimal performance and safety.

When paired with our burner management controllers, every aspect of your fuel train is precisely supervised. From perfecting purge timing to igniting flames, our systems monitor switch and safety conditions including the timing and adequacy of the purge prior to light-off, as well as the intervals allowed for getting pilots and main flames lit. It will also direct the safety shutoff valve to close if a problem is detected.

Fuel train components vary based on E&P specifications, control needs, safety requirements, gross BTU requirements, performance needs, and budget.

To learn more about our customized fuel trains and solutions contact us.