Pre-packaged Systems Offer Advantages for BMS Retrofit Projects

MARCELLUS/UTICA Tell us more about your project

Project Highlights

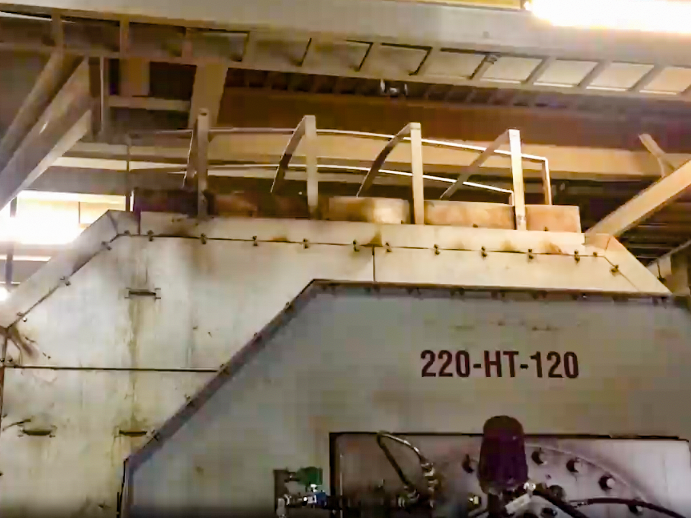

- 200+ Heated appliances were upgraded with prepackaged BMS solutions over a four month period.

- The project was completed within budget by efficiency gains through procurement, assembly, testing and installation.

- Average downtime per heater was two hours for the upgrade.

- The customer now has reliability, consistency and safety for their assets and employees by choosing a Profire prepackaged solution.

The Problem

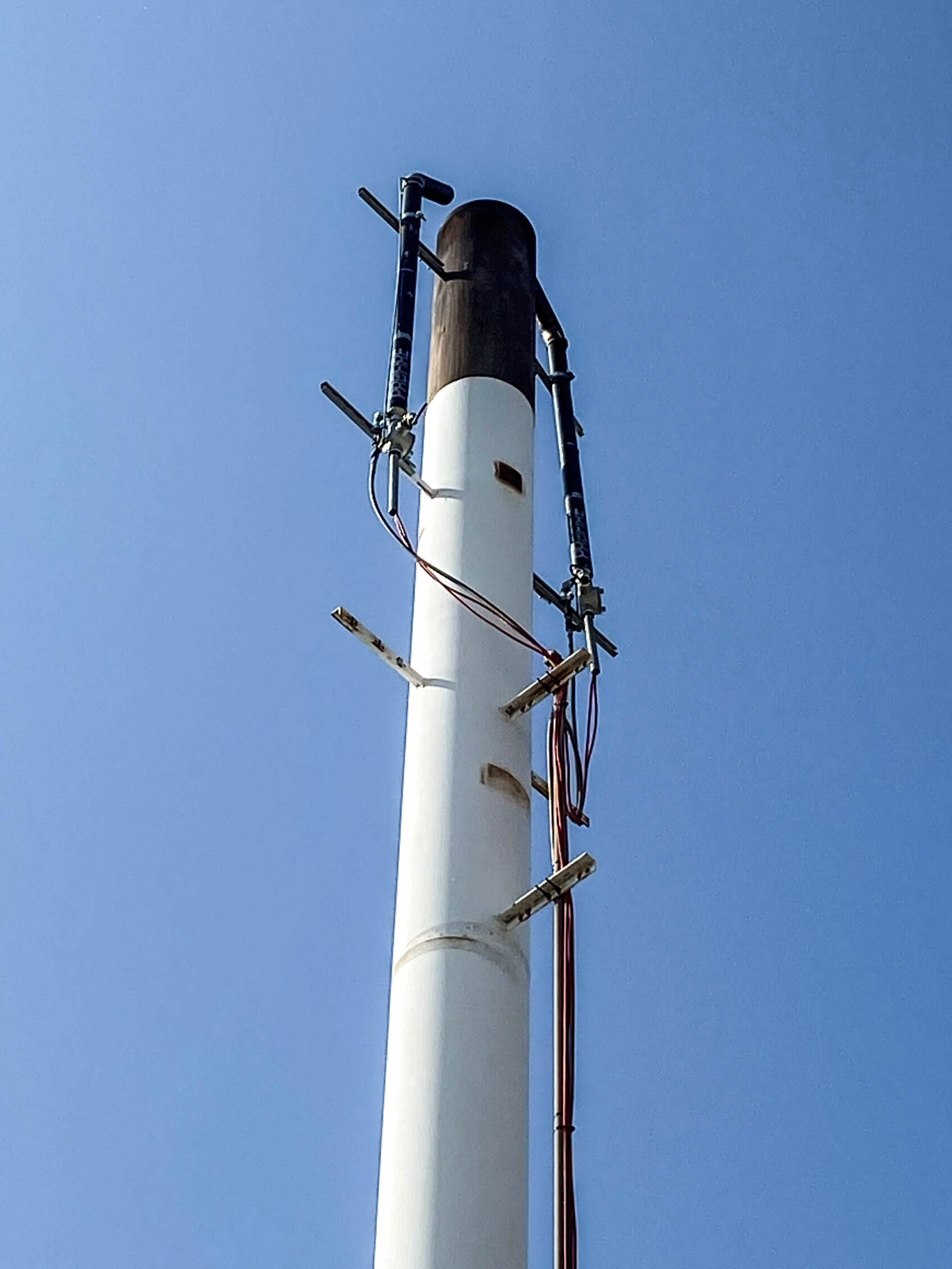

An upstream customer required a safer and more reliable burner management solution for their heated process equipment throughout their production field. The customer operated a wide variety of production equipment and wanted a consistent BMS solution to standardize their equipment on both new and older units.

Sound Familiar? Let's TalkBefore Profire

The Profire Solution

The proposed solution utilized a prepackaged fuel train and controller assembled and tested at the factory. The use of a prepackaged solution allowed Profire to build a high quality, consistent product while still meeting the challenges outlined by the customer. The versatile mounting options available on the prepackaged fuel train allowed the same design to be used on all the customer’s heaters. Utilizing a standard fuel train design enabled the customer to stock a minimum number of replacement parts to maintain all the company’s process heaters.

Get a Free QuoteAfter Profire

Ready to Optimize your Equipment?

Let Profire help with your Safety, Reliability, and ESG Initiatives

Get a Free QuoteRecent Projects

Our client had a unit with extremely dangerous and violent initial starts. The potential of equipment…

Operational failures experienced during inclement weather conditions coupled with inconsistent performance with the original pilot and…

Our client came to us feeling frustrated with the inefficiency of their Burner Management System. The…