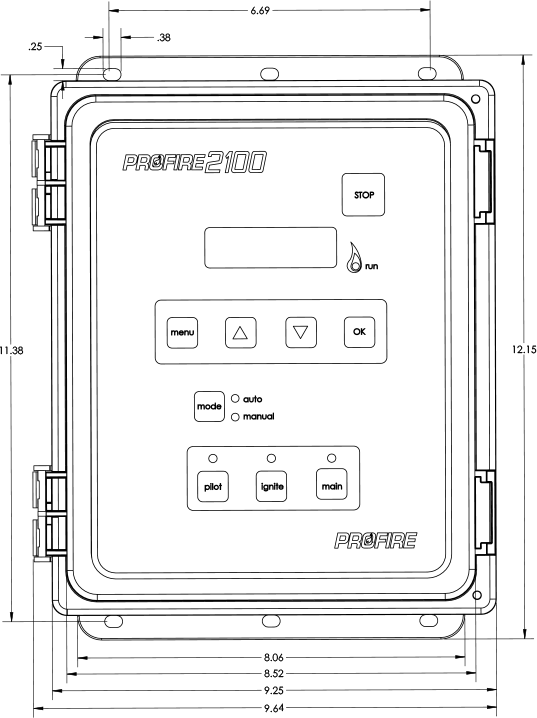

PF2100

The benchmark in natural burner management control, reliability, and performance for over 15 years.

Powerful and simple

With over 80,000 PF2100 controllers installed, it’s no question that the PF2100 has set a standard among operators, original equipment manufacturers, and engineers. The PF2100 offers natural draft burner management in a simplified and easy-to-use platform, allowing you to operate safely and efficiently.

Core Applications

-

Amine Reboiler -

Combuster

ECD/VDU -

Gas Production Unit (GPU) -

Glycol Dehydrator -

Heated Separator -

Heated Tank -

Heater Treater -

Line Heater

Why the PF2100?

- Integrated:

- High-temperature shutdown

- Temperature control

- History and event log

- Auxiliary thermocouple input

- Pressure & level switch contacts

- Status

- 4-20mA output

- Temperature out

- Valve control

- Low power design

- Solar & TEG ready

- Expansion Capability

- Modbus RS485

- Data logging with Modbus RS485

- 4-20mA Repeater (2 additional inputs)

- Tank Level

- Pressure transmitter

PF2100 CONTROLLER EXPANSION CARDS

-

Remotely monitor your controller settings and data

-

Add two additional inputs and echo your input level signal to a remote monitoring device

-

Log critical data locally and remotely

Download the PF2100 Product Sheet

Documentation

Tell Us About Your Application

A Profire Specialist Will Contact You Within 24 Hours

GET YOUR BMS COMPARISON GUIDE

PF3100 vs PF2200 vs PF2100 Download Profire's complete burner management comparison guide to find which controller best fits your applications.

GET THE GUIDE