Case Studies

Featured Project

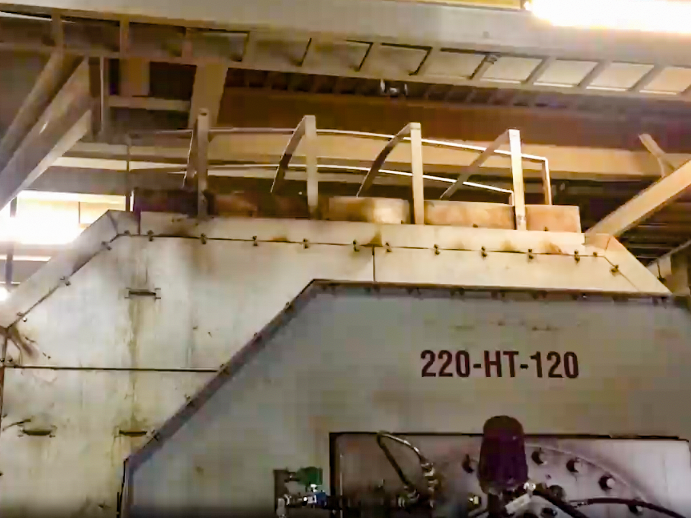

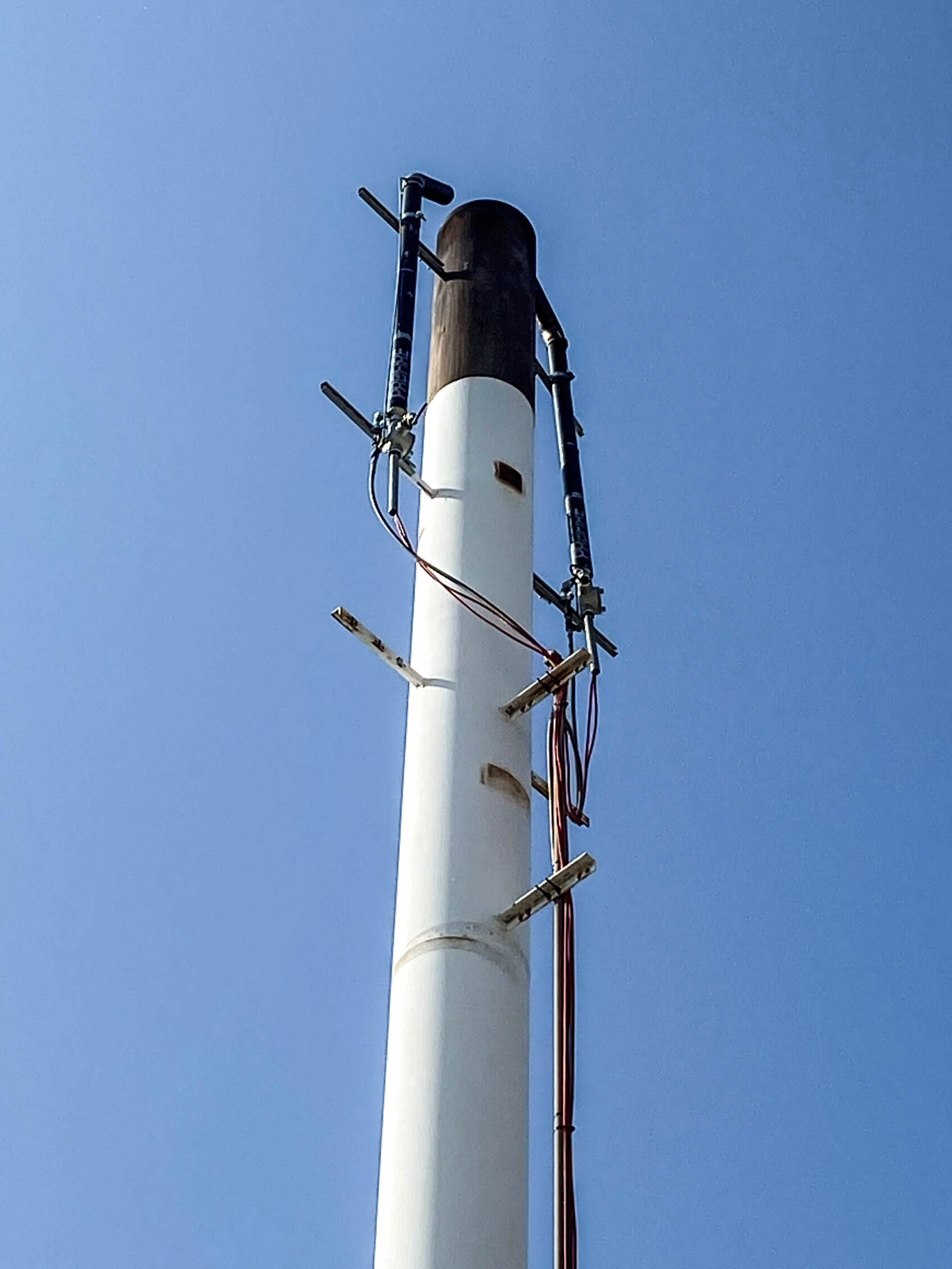

Vacuum Boiler – Natural Gas Line

CWT Boiler, Dry Line Heater, Pipeline Heater, Vacuum Boiler

After consulting with National Grid, the Profire Team recommended a PF3100 burner management system for the application. The PF 3100 platform provides a wide range of temperature control, process and ESD functions. The proposed solution included a Profire ignition electrode to allow automatic pilot re-lighting and reliable pilot flame detection. The system was further optimized for efficiency and reliability by the following changes:

- Replacement of the existing temperature switches with Type K dual head thermocouples

- Replacement of the millivolt operated gas valves with Asco solenoids controlled by the PF3100 controller

- Replacement of the existing vacuum switches with vacuum transmitters to allow connection to the PF3100

- Enabled Modbus features on the PF3100

National Grid was able to dramatically improve reliability, safety, and visibility of their vacuum boiler operation after the upgrades. The company can now easily view live heater conditions and adjust set points both onsite and remotely.

View Case StudyRecent Projects

Our client had a unit with extremely dangerous and violent initial starts. The potential of equipment…

Operational failures experienced during inclement weather conditions coupled with inconsistent performance with the original pilot and…

Our client came to us feeling frustrated with the inefficiency of their Burner Management System. The…

Ensign was experiencing nuisance shutdowns with limited safety I/O. The heater was going down 2-3 times…

The client purchased a second-hand Bryan Boiler with outdated controls and inefficient air to fuel ration…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

An upstream customer required a safer and more reliable burner management solution for their heated process…

It was critical for National Grid to meet compliance standards and create a safe working environment…