A solenoid is a coil of electrical wires that transforms into an electromagnet field when electricity courses around and through the coil. By introducing a metallic core within the coil, the electromagnetic force is amplified leading to movement.

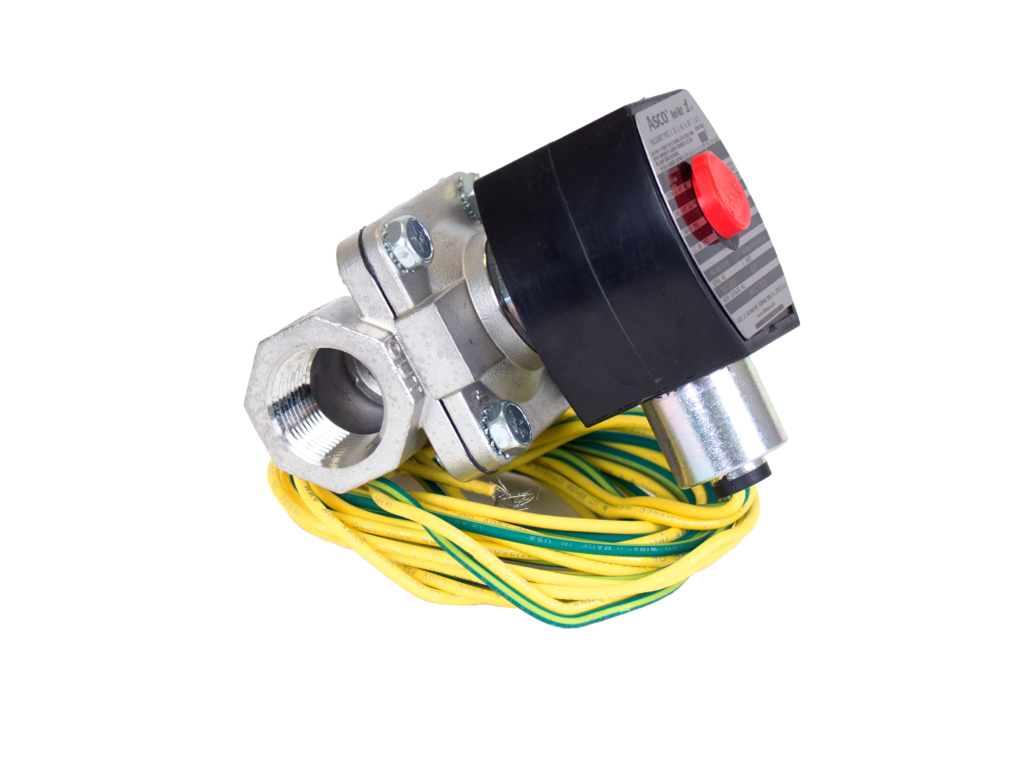

Because of its versatility, solenoids are used in many applications, including those involving solenoid valves. These valves control fluid flow in piping systems by utilizing a metallic plunger. Upon energizing the coil, the plunger shifts to either block or open the orifice for fluid passage. There are two main types of solenoid valves – “normally open” and “normally closed.” In the former, the orifice is closed during energization, while in the latter, the plunger opens the orifice when electricity is applied.