Flame Arrestors are an integral component to the overall functionality and safety of an industrial combustion system. As a leader in industrial heating applications, Profire understands the critical role these devices play in ensuring the safe handling of combustible gases while also mitigating fire hazards.

The main functions of a flame arrestor include:

- Operator and site safety

- Adequate air supply for complete and efficient combustion

- Aid in noise reduction of the heater system

- Reduce air contaminants from entering the firetube

The integration of flame arrestors has minimized fire risks associated with natural draft and firetube applications across various industries. From Oil & Gas to Biogas, Pulp & Paper, Landfill, and more, these devices play a pivotal role where combustion is involved. By effectively controlling flame spread in industrial heating vessels, flame arrestors have become an irreplaceable safeguard against the high risks posed by combustible materials.

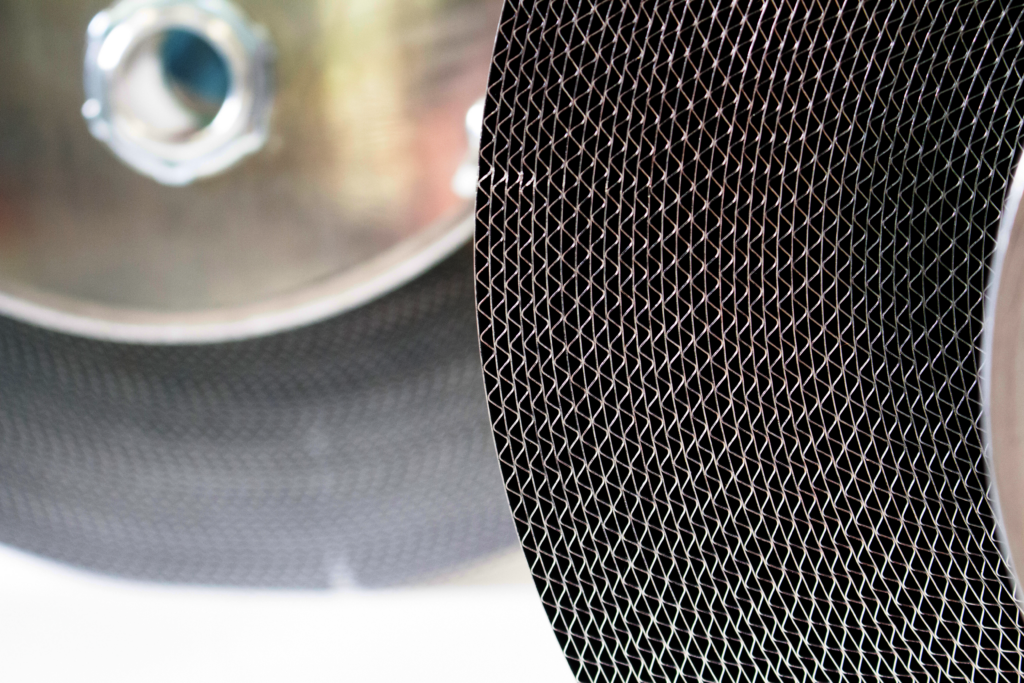

Flame Arrestor Cells

Let’s dive into the heart of these devices — their housings. Each is equipped with aluminum flame cells functioning as more than just barriers; they are strategic disruptions in the path of a flame, forcing it through multiple narrow channels. The brilliance of the cell is in its mesh or element structures.

Porous by design, the cells permit gases or vapors to pass through under normal operating conditions. But when a flame dares to enter the arrestor’s body, this mesh becomes a formidable opponent. It disrupts the flame front, cooling and quenching the hot gases that are fueling the flame.

The channels which are intricately small, don’t offer the flame enough room to sustain combustion.

The result is a quenched or extinguished flame, effectively preventing backflashing. This is where our flame arrestors excel — safeguarding your operations while helping you achieve your industrial heating goals.

Types of Flame Arrestor Bodies

Flame arrestor bodies are designed in multiple styles and configurations. Selecting the proper body is critical in the heater design process to ensure proper air flow and to support complete combustion. They are composed of various types of metals, mesh screens and cells dependent on the application they will be used for.

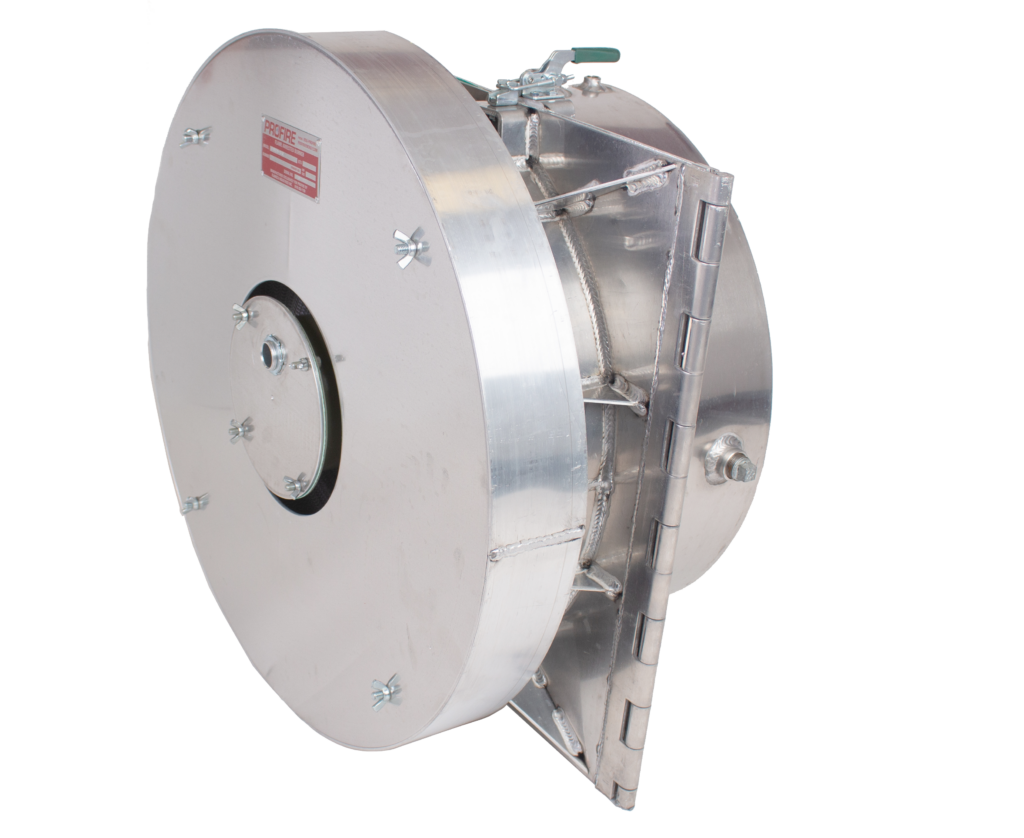

Available in box style, hinged and clamped, or single body, each flame arrestor is designed with varying heating capacities:

- Single Body – Typically used for single fire tube applications with lower BTU/Hr requirements.

- Hinged and Clamped – A two-piece design which allows easy fire tube access for service and maintenance.

- Box Style – Designed for high BTU/Hr applications that require multiple flame cells through the housing.

In addition to their heating capacities, the housing details are also key when choosing the right fit for your application. Hinged and clamped flame arrestors are ideal for situations where regular inspections are a must. Alternatively, if you’re looking for robustness or permanent installations, single body and box style flame arrestors stand out with their sturdy designs. All of the designs are available in standard sizes, or custom sizes to suit your specific combustion process requirements.

Compliance and Safety Benefits

Flame arrestors are more than just beneficial; they’re a key requirement in numerous industrial environments. Their role is critical, not only for regulatory compliance but also for ensuring the safety of your team, safeguarding your equipment, and fostering a secure workspace. Numerous case studies endorse their efficacy in preventing incidents, reinforcing their indispensable role within burner and combustion systems.

Regulatory authorities, including EPA and OSHA, enforce stringent safety measures to curb workplace hazards. Integrating flame arrestors can streamline your compliance efforts. Once installed, regular inspections and cleaning are pivotal to maintaining performance as blockages in a flame cell can dramatically impact the efficiency and emissions produced during the combustion process. Regular staff training is also essential to ensure everyone is well-equipped to handle and maintain these devices correctly. Non-compliance can lead to severe repercussions, including substantial fines or even suspension of your operating license.

At Profire, we’re not just about delivering products; we’re your trusted partner in providing robust, safe, and efficient burner and combustion management solutions. When you’re ready to take the next step in enhancing your industrial heating performance with our flame arrestors, our Experts are just a phone call away!