At Profire we produce various configurations of burner management systems (BMS) and controllers that are specifically designed to ensure reliability and efficiency for your specific heated application. Burner management systems are used in a wide array of industries that require a safe and reliable way of heating appliances where precise temperature control is required. They include many functioning components that monitor the temperature of the vessel, operate fuel trains, and support automatic soft starts and shutdowns. Additional components have the ability to monitor flame status and other interlock signals allowing for increased safety of the overall system. A BMS can be customized to enhance your application by our engineering and design team. When constructing a solution there are several factors that can affect the reliability of your BMS system. Let’s take a look at what can alter the reliability and lifespan of your BMS.

Burner Management System Reliability

Quality Products used in Profire burner management system

Each of our systems are constructed with top-quality products. A complete system can include a controller, fuel train, and burner. Some of the elements included in a complete solution are dependent on whether the system is being used in conjunction with a natural or forced draft burner. Other elements of a burner management system that will have an effect on reliability include the flame arrestor on a natural draft system or the air blower on a forced draft system. These need regular maintenance because having the proper air supply and amount of air is absolutely critical to achieve efficient combustion. Our team of experts at Profire can help determine which of our products would provide the most reliable system for your application.

Failure rate of a BMS

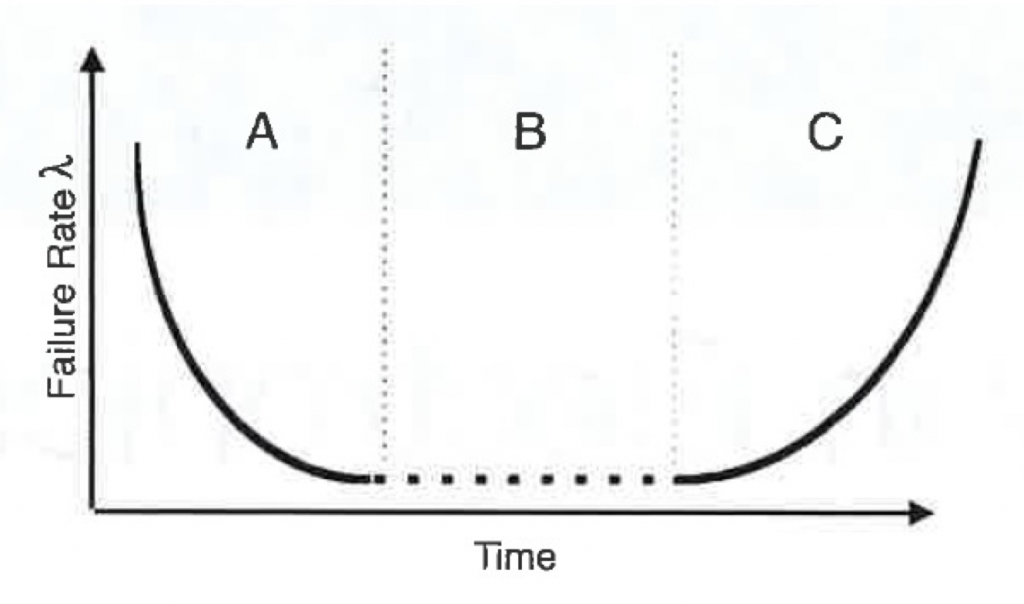

When looking at the reliability of a BMS system, the first aspect to review is its failure rate. This is defined as the likelihood of a critical component failure and the percentage of components failing per unit time. Typically, there are three key time periods of expected reliability during a BMS’s lifespan. This is illustrated in what is called a “bathtub” curve as shown below.

The initial curve or section A is considered the BMS’s Infant Mortality Region. This is when the product is initially launched and can experience failures. The reason for these failures could be caused by defective products or components. Another possible reason for burner mortality is improper configuration or commissioning when the system was initially set up. Both of these issues can be corrected by having our service team inspect your system. Once one of these issues are determined to be the cause of the failure, malfunctioning parts can be replaced, or the system can be recommissioned. Following these maintenance updates, your system will begin to run properly and efficiently.

Section B, or the flat portion of the curve, is described as the Useful Life Region. During this period of time, product failure is minimal as the system has stabilized into a relatively constant and low failure rate. With a regular preventative maintenance schedule, you can extend this portion of your burner’s lifespan.

The final stage of life for a burner and where the curve begins to heighten again due to failures is in Section C or the Wear Out Region. This occurs when components of the BMS begin to wear and approach the end of their useful lifespan.

How do you calculate the failure rate?

The Mean Time Between Failures (MTBF) is the inverse of the failure rate (MTBF = 1/ λ)

Reliability, R(t), is often defined as the probability that a piece of equipment operating under specified operating conditions shall perform satisfactorily for a given period of time. It can be calculated using the following equation:

R(t) = e – λt = e -t/MTBF

The useful life of a BMS can be estimated using Weibull Analysis. It informs us where the BMS is on the bathtub curve, estimating how much time before wear out will occur.

The two-parameter Weibull Analysis involves fitting the lifetime data of individual BMS units to the following cumulative distribution function:

F(x) = 1 – e –(x/α)^β , for x > 0

Where α represents the characteristic life of the BMS and β indicates where on the “bathtub” curve the BMS is.

Ways to maintain your BMS

- Regular maintenance – At Profire our skilled preventative maintenance team will inspect your equipment for any irregularities or diminishing parts. Replacing some of the instrumentation within the system as needed can provide a more reliable and efficient system.

- Upgrade firmware – When you upgrade your Profire product firmware, it helps keep your system updated on the latest safety codes and new functionality. Any firmware updates for your Profire system can be found here.

- Safety Standard Compliance – Maintaining your system to adhere to any changes in safety standards is an important part of increasing its lifespan. As safety standards change, you’ll want to upgrade sections of your system’s requirements. Our team offers you support every step of the way.

At Profire our burner management systems are designed for reliability and efficiency. Our skilled team of engineers specifically design the solutions that best fit your application. We deliver quality, purpose-built products that give you exactly what you need when you need it. For more information or to speak to an expert please contact us.