Amine Distillation – Cabin Heater

ENSIGN NATURAL RESOURCES - EAGLE FORD Tell us more about your project

Project Highlights

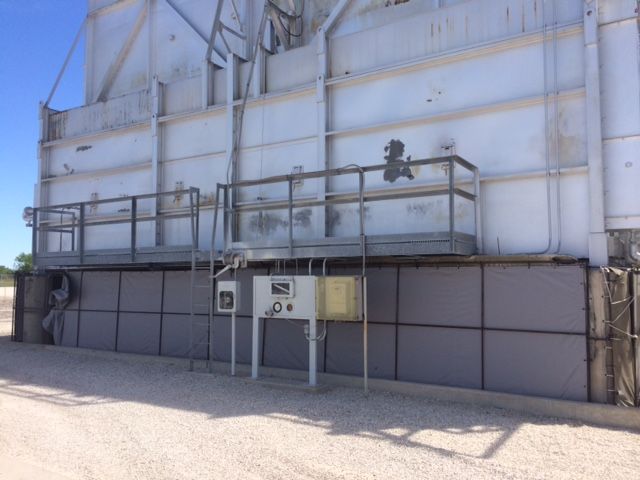

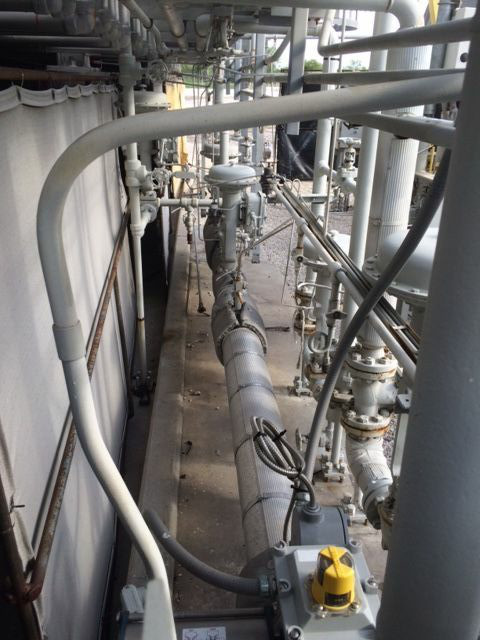

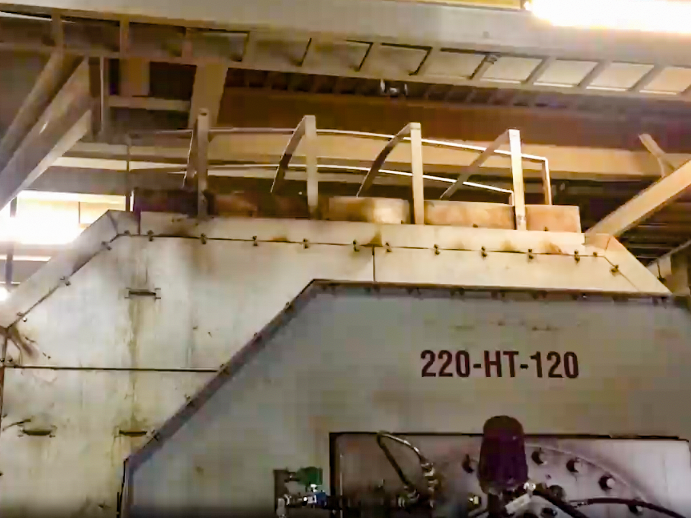

- 12-Burner Cabin Heater - 30MM BTU with 12 independent fuel trains

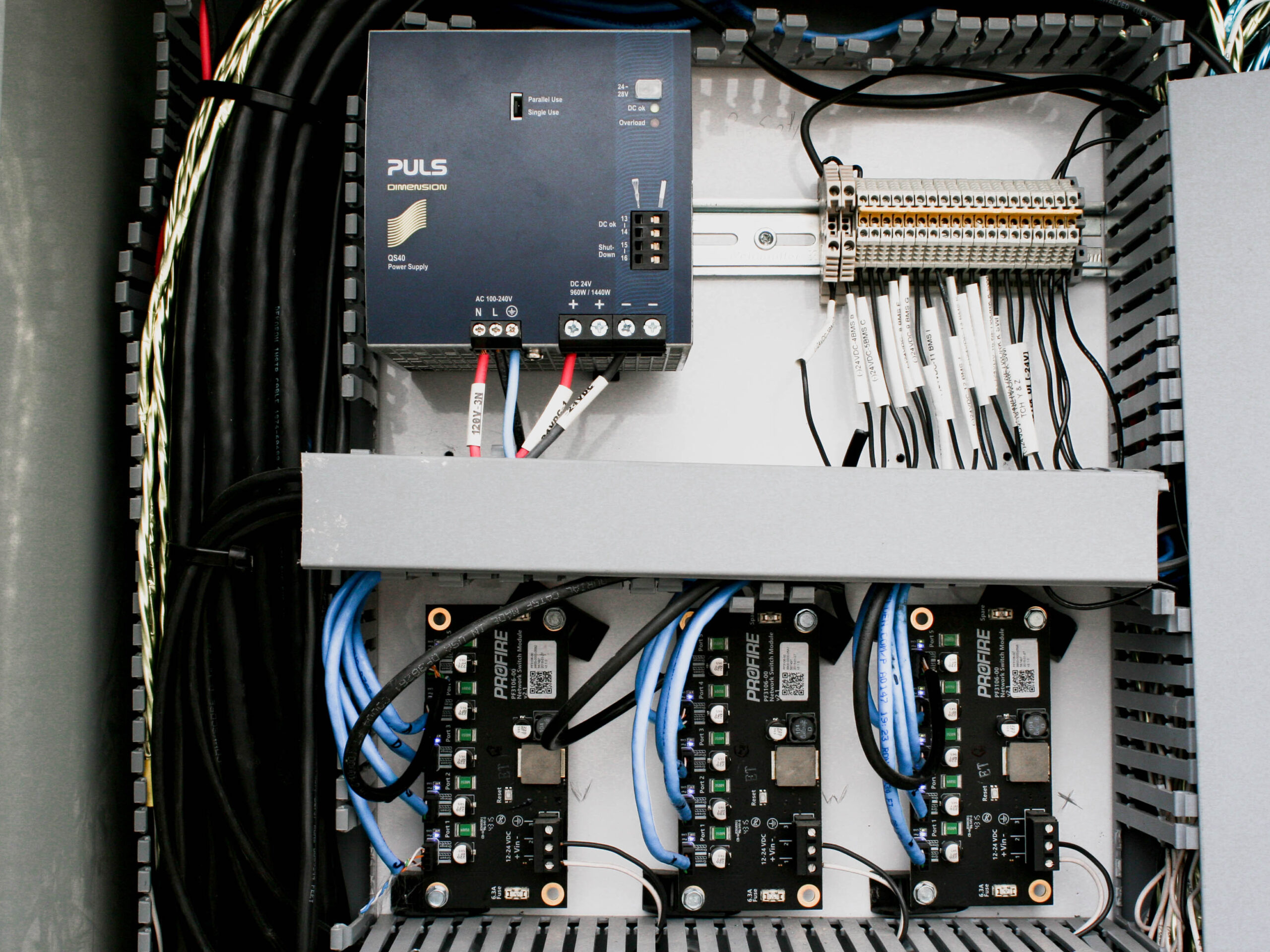

- +250 Safety I/O Controlled and Monitored from User Interface in the Control Room

- Redundant Temperature Measurement/Redundant Networks

- Client was able to see ROI in less than eight months.

The Problem

Ensign was experiencing nuisance shutdowns with limited safety I/O. The heater was going down 2-3 times a day due flame failure. Operators and I&E personnel were constantly manually relighting the heater 2-3 times day! Ensign required a safe and reliable solution that met their budget.

Sound Familiar? Let's TalkBefore Profire

The Profire Solution

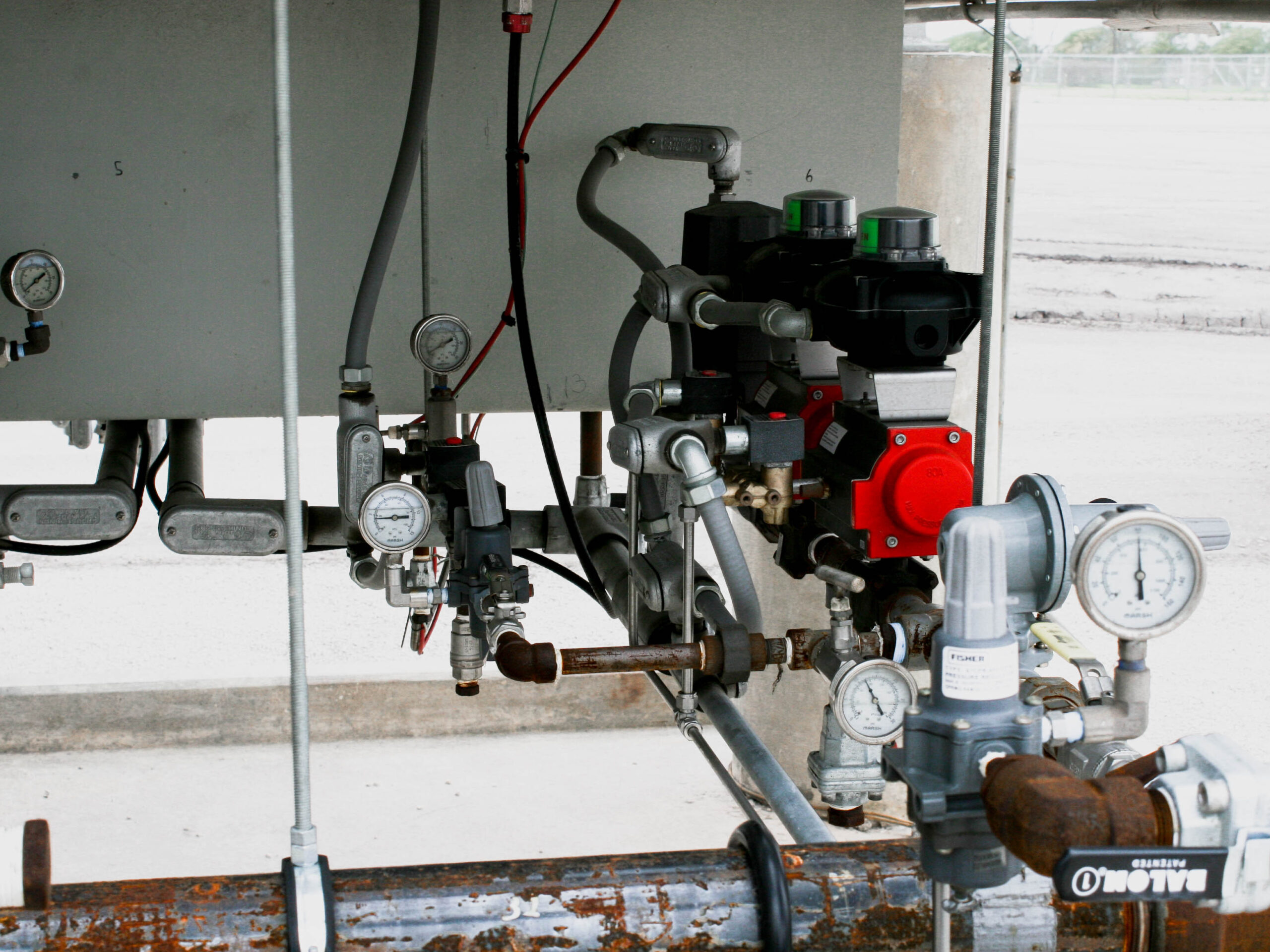

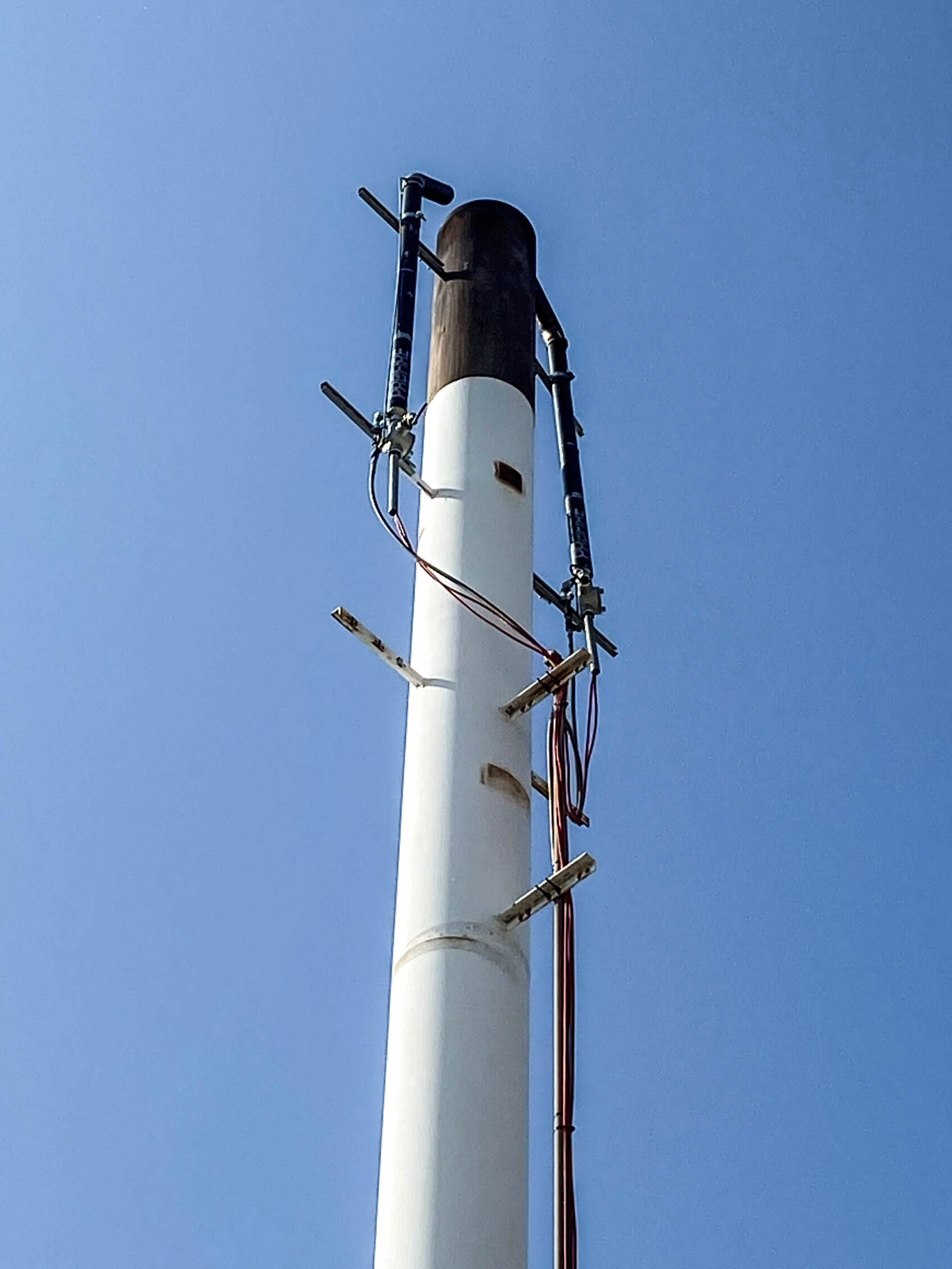

Ensign needed to meet several safety standards (NFPA, ASME & API560). Profire proposed our 3100 Platform due to the complexity and I/O concentration of the project. Numerous discussions revolved around the accurate temperature measurement from the distillation column located 380′ away from the heater. Our design included a quad thermocouple and split the redundant temperatures on redundant networks. 12 individual fuel trains control 12 independent temperature controls valves. This allowed the client to see a 45%+ gas savings due to proper gas regulation and modulating controls for each burner!

Get a Free QuoteAfter Profire

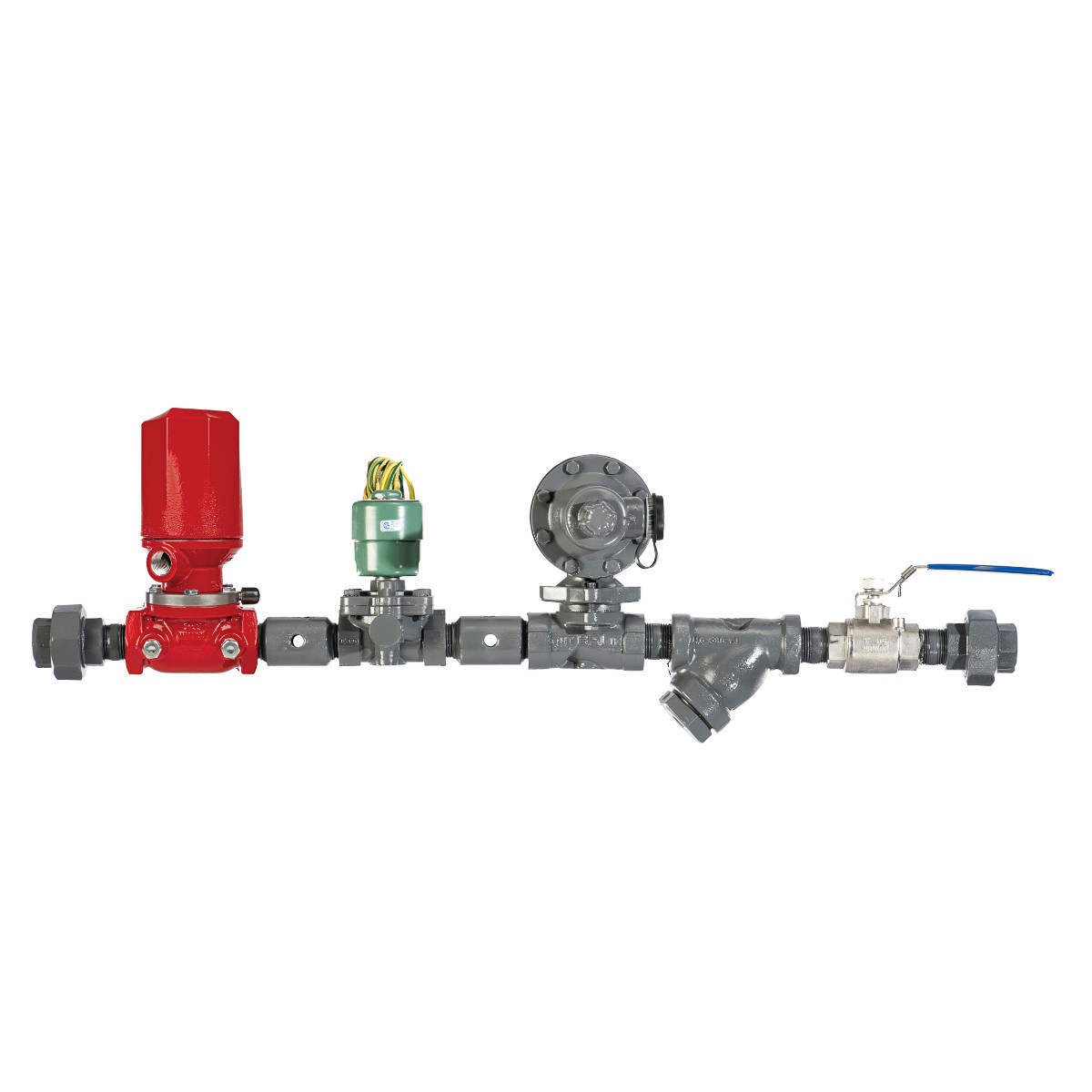

Key Products Used

Ready to Optimize your Equipment?

Let Profire help with your Safety, Reliability, and ESG Initiatives

Get a Free QuoteRecent Projects

Our client had a unit with extremely dangerous and violent initial starts. The potential of equipment…

Operational failures experienced during inclement weather conditions coupled with inconsistent performance with the original pilot and…

Our client came to us feeling frustrated with the inefficiency of their Burner Management System. The…