Line Heater Upgrade

Marecellus, West Virginia Tell us more about your project

Project Highlights

- Replaced non-functioning control box with PF2100 controllers

- Ensured safe operation by installing a fuel train with safety shutoff and slow start TCV

- Removed old arrestors and installed 2 new arrestor boxes

- Tuned both burners to provide necessary heat that was previously unattainable

- Provided automatic relights and many safety shutoffs to improve both safety and reliability of the heater

The Problem

This heater was unable to achieve the necessary temperatures required for operations because of airflow and improper burner installation. The operators had to prop the door open to keep it running and would frequently blow out. There was no auto ignition to re-light or safety shutoff to prevent gas from escaping

Sound Familiar? Let's TalkBefore Profire

The Profire Solution

The Profire Team installed new arrestor housings supplied by the customer to allow adequate secondary air flow for complete combustion. In addition, the outdated fuel trains were upgraded to provide additional reliability, safety and independent burner tube control. Two Profire PF2100 controllers were installed to provide temperature control, auto re-lights and flame detection for safe operation. Overall, the Profire solutions were able to significantly improve the operation of the heater by achieving the desired heat output in a safe and reliable system.

Get a Free QuoteAfter Profire

We had a project that had been sitting unfinished for over a year because we couldn’t find anyone who could complete the work. We asked Profire - whose techincians were already installing a burner management system with our previously purchased flame arrestors and burners sitting on site - to inspect the heater and give us a quote. It was a large 2 burner line heater with new flame arrestors waiting to be installed. When Profire visited our site, they provided a complete BMS solution which included the service work and installation. After the system was installed, we were able to heat the gas to the expected level which had not been accomplished for over 2 years. Prior to our installation, we had to prop the arrestor door open to keep it running and visited frequently to re-light the pilot. All site visits stopped after Profire improved our systems.

Mike Mitchell, Dominion Energy

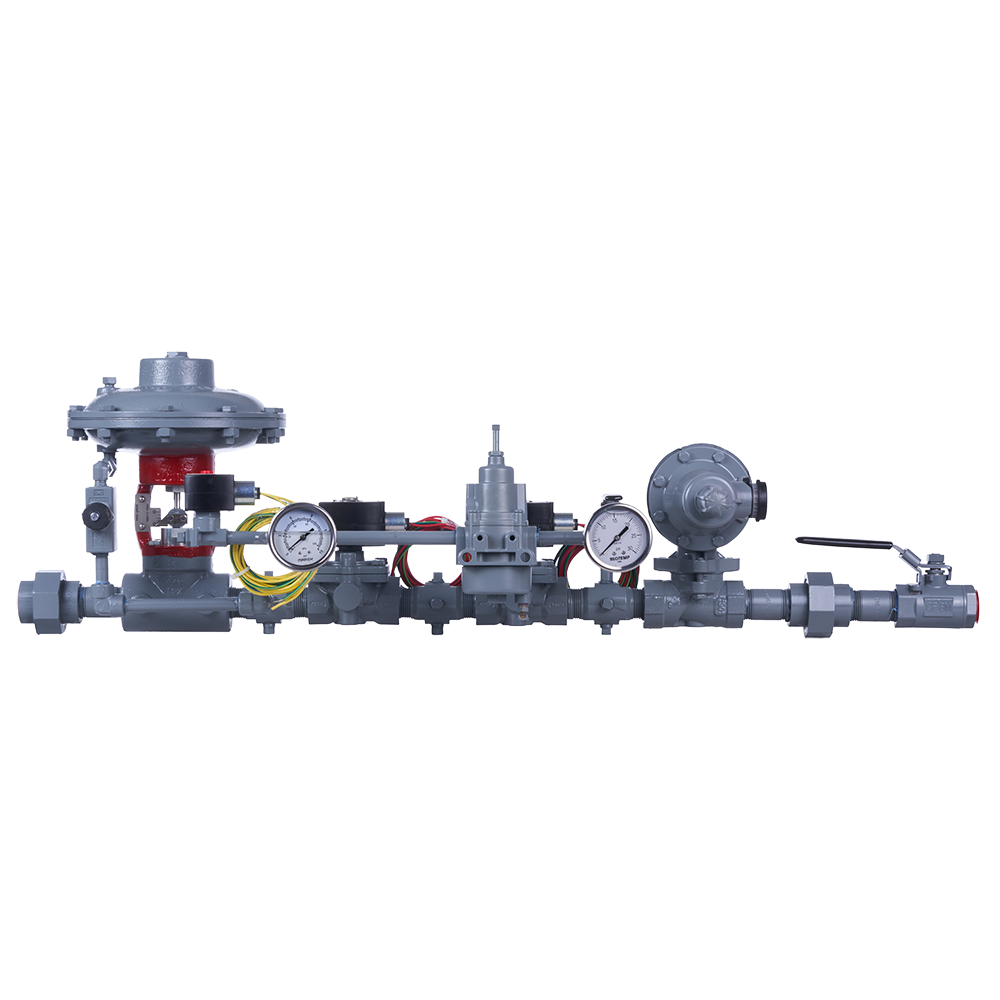

Key Products Used

Ready to Optimize your Equipment?

Let Profire help with your Safety, Reliability, and ESG Initiatives

Get a Free QuoteRecent Projects

The customer specializes in ambient-temperature drying processes that convert juice extracts into shelf-stable powders, while preserving…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

One of our long-term customers faced the serious risk of regulatory penalties at the local, state,…