Fuel Train Configuration Factors

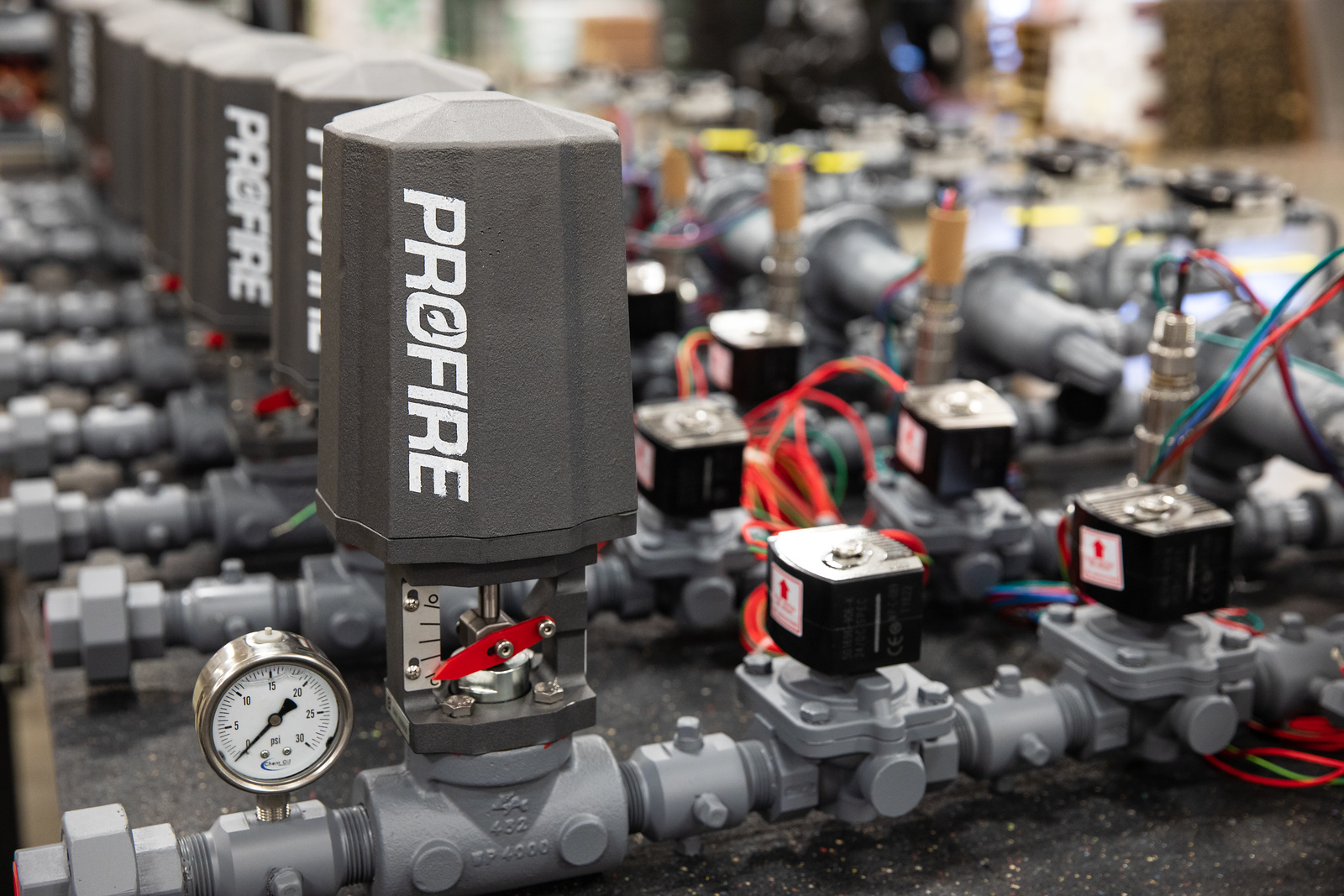

Fuel trains are integral for controlling the proper flow of gas into your natural or forced draft burner as part of your complete combustion control system. Each fuel train is customized with specific components to meet your application requirements and location standards. It can be designed for a wide range of BTU applications with various configurations including double or single block safety shutoff valves, soft start pneumatic or electric control valves, and pressure monitoring devices. Ensuring your fuel train is constructed with top-quality components including pressure regulators, restrictor valves, control valves, pressure switches, or pressure transmitters will increase the safety, dependability and overall efficiency of your system. But how do you choose? Our team of experts at Profire will conduct a complete evaluation of your application, researching all the requirements and standards applicable to your use and location. Ensuring your system meets all safety and compliance standards is an important step in designing a customized fuel train. To ensure your fuel train runs efficiently for your application there are a number of key elements to consider, let’s take a look at some of the factors that affect fuel train configurations.

Available Space

The first thing we will look at is the space available for the installation of your fuel train. Both inline fuel trains and compact solutions, such as the Profire Pro-QS or Pro8, offer configuration options to best fit your space requirements. They are available pre-assembled for quick installation or can be customized for your specific application. When installing a fuel train, it is important to consider future maintenance requirements and provide adjacent space in the surrounding area. These details are all important to the overall efficiency and lifespan of your fuel train.

BTU Rating

The size of your process heater plays a role in the BTU requirements needed for your system and the fuel train that will best suit those specifications. Our fuel trains come in a variety of BTU (British Thermal Unit) rating configurations ranging from 0-5 MMBTU (Million British Thermal Units) or higher depending on your application. BTU is defined by the amount of energy required to heat the substance within your appliance. The components and configurations of a fuel train change depending on the heat output of your system. Correctly matching the BTU for your appliance provides increased efficiency and reliability, as well it affects the overall lifespan of your system. For example, fuel trains with a rating greater and equal to 12,500,000 BTU/hour require double block and bleed valves for additional safety. To ensure the highest efficiency of your fuel train all of these factors must be considered when building a fuel train.

Location

Whether your site is located in the United States or Canada there are standards and codes that your equipment must adhere to. This includes specifications for the components and configurations used in the construction of your fuel train. In the U.S. fuel trains must meet the National Fire Protection Association Standard for fluid heaters (NFPA 87) or the American Society of Mechanical Engineers Control and Safety Devices for automatically fired boilers (CSD-1). In Canada, fuel trains must meet the Canadian Standard Association’s code for the field approval of fuel-related components on appliances and equipment (B149.3). Both departments provide typical diagrams of fuel trains that manufacturers and operators can use as a guide to ensure compliance. The interpretation of these standards are followed by the Authority Having Jurisdiction (AHJ) which can be comprised of different individuals authorized within a particular location.

Budget

Budget can also play a role in depicting the type of fuel train chosen for your production heater. Depending on your budget and requirements, Profire offers complete burner management solutions including the PF3100, PF2200 and PF2100 controller series that work with your fuel train to ensure your system continues to run safely and efficiently.

For more information on our solutions and products contact us.