Low Temperature Spray Dryer

For manufacturing organic juice powders. Tell us more about your project

Project Highlights

- Maintain temperature below 41°C (105.8°F)

- Custom Engineering & BMS Design

- Industry Regulation Adherence

- System Installation & Servicing

- System Startup & Commissioning

- System Performance Analysis

The Problem

The customer specializes in ambient-temperature drying processes that convert juice extracts into shelf-stable powders, while preserving their natural color, flavor, aroma, and nutrient content. Their drying process is designed specifically for heat-sensitive botanicals and relies on gentle, low-heat methods to produce clean-label, minimally processed powders without thermal degradation.

They faced two main challenges. Their existing system struggled to maintain the low, precise temperatures required to meet their quality standards, and they needed additional production capacity to keep up with growing demand.

To address these challenges, they began exploring a larger, more advanced system that could convert liquid juice into fine, shelf-stable powder at a higher throughput. The new system also needed to hold strict process temperatures below 41°C (105.8°F), which required improved gentle-drying capabilities to protect the nutritional integrity of their products throughout the drying process.

Sound Familiar? Let's TalkThe Profire Solution

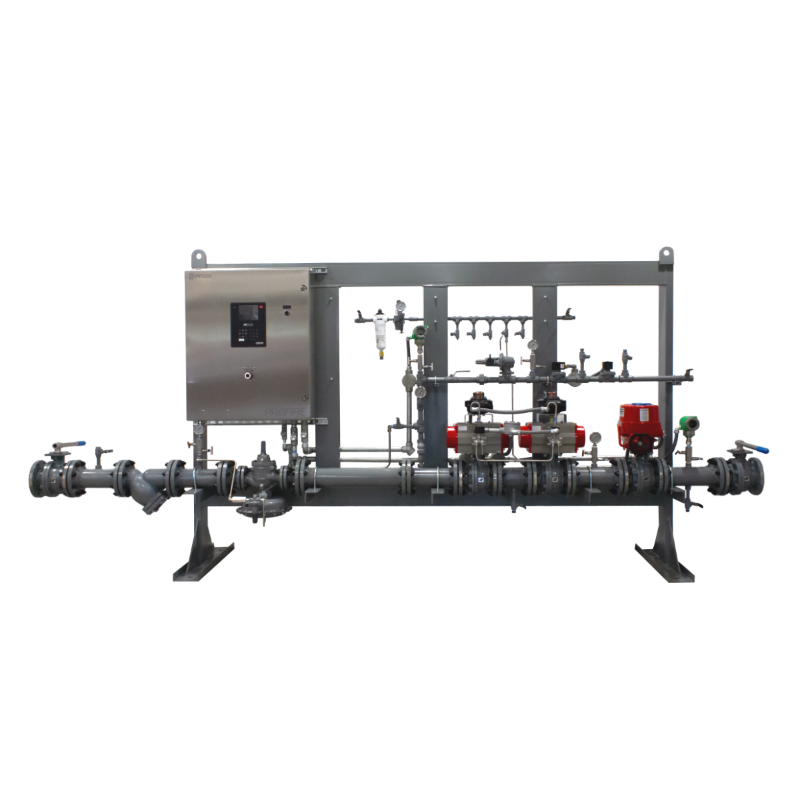

To support low-temperature spray drying at a larger production scale, the system was built around the PF3100 BMS Control Panel. The dryer needed to remain below 41°C (105.8°F) to protect nutrient quality, and the PF3100 gave operators the precision needed to hold that narrow range. The system delivers 16MM BTU/hr through a high-efficiency burner with specialized nozzles, while still maintaining stable performance at low firing rates.

Although the PF3100 can support up to 64 pilots and 16 fuel trains, the main advantage for this project was its accuracy. The controller maintains steady burner output and supports the fine gas-flow modulation required for gentle drying. A custom rack-mounted fuel train helps ensure smooth, predictable gas adjustments, so the dryer stays inside the customer’s temperature window.

The customer also wanted better visibility into day-to-day performance. With Modbus communication and data logging, the PF3100 integrates directly with their facility controls, giving operators real-time access to temperature trends and system behavior from their control room. Profire also supported the airflow design to ensure that heat was distributed evenly across the drying chamber, which is essential when processing heat-sensitive botanicals.

Every part of the setup centered on the customer’s process and their strict temperature requirements. The result is a dependable spray drying system that protects product quality, reduces operator workload, and gives them a platform they can continue to expand as production increases.

Get a Free QuoteAfter Profire

Ready to Optimize your Equipment?

Let Profire help with your Safety, Reliability, and ESG Initiatives

Get a Free QuoteRecent Projects

The customer specializes in ambient-temperature drying processes that convert juice extracts into shelf-stable powders, while preserving…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

One of our long-term customers faced the serious risk of regulatory penalties at the local, state,…