A look at the differences between natural and forced draft burners

What is the difference between natural and forced draft burners?

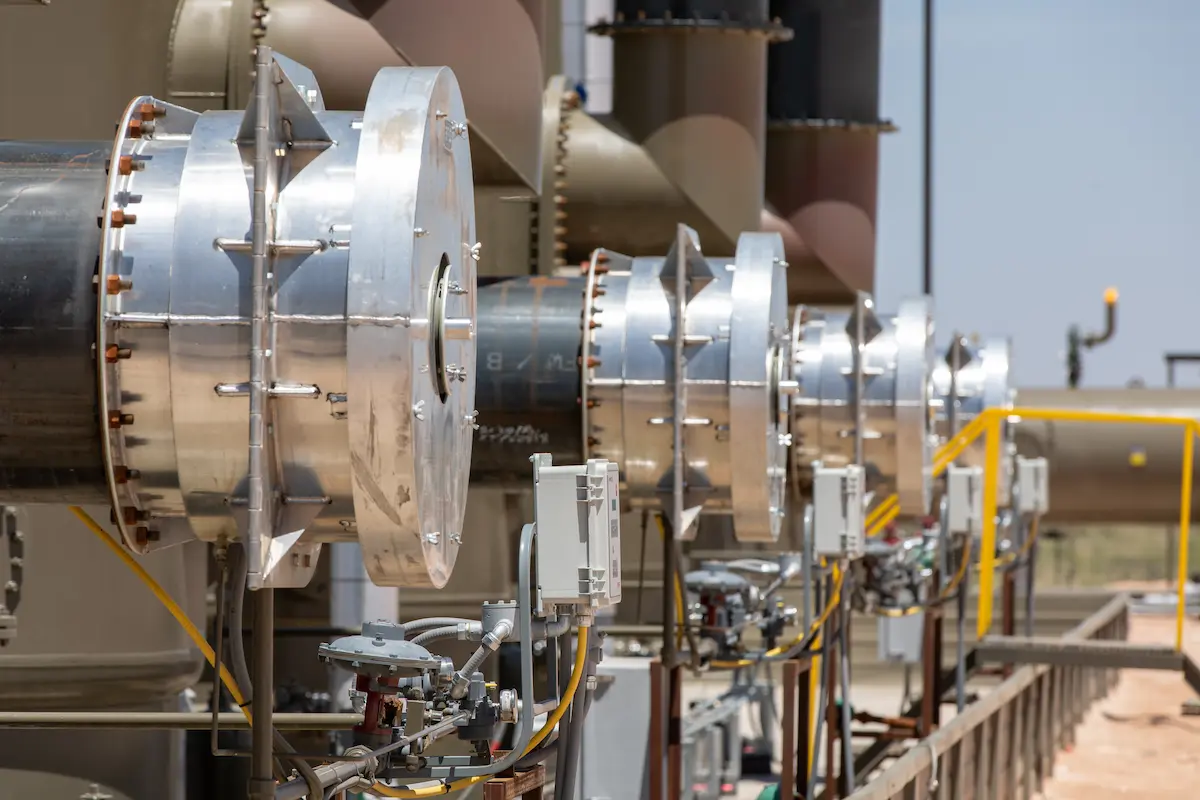

Natural and forced draft burners differ in how they create airflow. They are used in several industrial applications that require the use of heat to achieve and utilize controlled combustion for a specific heating process. Natural and forced draft burners are used process heating appliances in the production, transport, and refinement of many day-to-day products. Both are unique in their functionality to control and produce the required heat and to maintain accurate temperatures for each specific application.

How do natural and forced draft burners work?

When looking at natural and forced draft burners the word ‘draft’ describes the difference between the atmospheric pressure and the existing pressure of a gas passageway or combustion chamber that causes the gas and air to move. The firetube and stack are usually built in a cylinder shape to provide the optimal structure for this air to flow. Both natural and forced draft burners are used to mix fuel and air to maintain a safe, stable, and efficient flame. They run as part of a complete system that contains a burner, secondary air control, pilot, orifices, fuel train, and a burner management system controller. The substances that are being heated can include fluids, gases, or recycling material. Natural draft burners use the difference in density of hot and cool air or flue gases to create pressure to move the fluids through the combustion chamber. Flue gases are a mixture of gases resulting from burning fuel or other materials. Forced draft burners use power to create mechanically assisted air pressure within the system to move air or flue gas. This allows for a higher level of consistency and control of the appliance. Both types of burners are available in a variety of sizes and have a variety of industrial uses.

Industries using natural and forced draft burners include:

- Oil and Gas

- Power Generation

- Mining

- BioTech

- Petrochemical and Refining

- Renewables

- Landfill

- Agriculture

- Municipal

- Food and Beverage

- Construction and Infrastructure

- Pulp and Paper

Key elements of a natural draft burner

Natural draft burners rely on a draft to be produced from the temperature created in the combustion process of flue gas. It utilizes the principles of combustion, draft, and pressure to produce the airflow necessary to support the intended performance of the application. With the lower cost of running a natural draft burner, as well as the reduced maintenance requirements, they are often a cost-effective choice for industrial applications. They do not require power, a fan, or a blower to run. With very minimal moving parts natural draft burners are a low-maintenance and reliable long-term choice. Profire’s Eclipse Compound Injector Burner, M7, and M5 Series of natural draft burners have proven to be effective for industry leaders who require reliable solutions for their applications without the need of forced draft pressure. Profire has purpose-built burner management system controllers specifically designed to monitor natural draft burners to increase the efficiency and safety of an entire system. Profire’s PF2200 series includes dual and single burner options allowing you to customize the solution that is right for your application. The PF2200-DB has been designed to enhance the performance and control of natural draft firetube applications. In addition, Profire’s PF3100 series has been purpose-built for compatibility with either natural or forced draft burners and can be customized for use with multi-burner and multi-pilot applications. The PF2100 Series offers a flare ignition and incinerator controller. Some of the applications where a natural draft burner is used include:

- Direct Fired/Convection Process Heaters

- Cabin Heaters

- Heat Medium Heaters

- Process Heaters

- Thermal Oxidizers

- Amine & Glycol Reboilers

- Emulsion Treaters

- Gas Production Units

- Combustors & Flares

- Condensate Stabilizers

- API Fired Heaters

Key elements of a forced draft burner

One of the key elements that differentiate forced and natural draft burners is the use of power to function. Power is used to create a consistent and controlled intensity of airflow in the combustion chamber with a forced draft burner. This results in a higher efficiency rate for users as the system will require less fuel consumption and doesn’t rely on atmospheric conditions for its functionality. Forced draft burners have added complexity because of the use of mechanical parts and the need for devices to monitor the presence of airflow. Also, when using a forced draft burner it is important to note that in some uses the water condensation from the combustion process will need to be collected and disposed of. The combination of these factors can increase the overall cost and should be considered when choosing the right system for your application. To ensure the accuracy and dependability of your system, Profire’s PF3100 controller, and PF2200 Forced Draft controller have both been specifically built for forced draft firetube and fan-assisted appliances. These controllers are part of Profire’s complete solutions that offer ultra-low power consumption and less fuel pressure requirements. Some of the applications for a forced draft burner include:

- Direct Fired/Convection Process Heaters

- Cabin Heaters

- Heat Medium Heaters

- Process Heaters

- Thermal Oxidizers

- Amine & Glycol Reboilers

- Emulsion Treaters

- Gas Production Units

- Combustors & Flares

- Condensate Stabilizers

- API Fired Heaters

There are several factors to consider when you’re choosing between a natural or forced draft burner including cost, efficiency, maintenance requirements, access to power, simplicity, and compatibility with your system requirements. For more information, speak to a Profire expert about the right solution for your application.