Case Studies

Featured Project

Low Temperature Spray Dryer for Organic Juice Powders

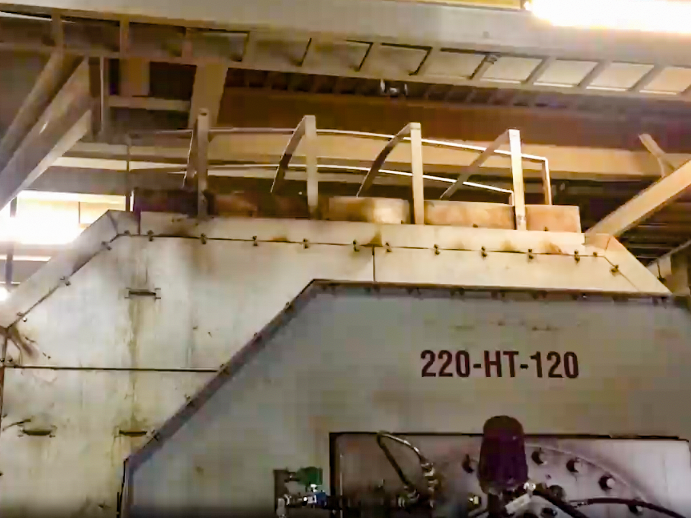

Spray Dryer

To support low-temperature spray drying at a larger production scale, the system was built around the PF3100 BMS Control Panel. The dryer needed to remain below 41°C (105.8°F) to protect nutrient quality, and the PF3100 gave operators the precision needed to hold that narrow range. The system delivers 16MM BTU/hr through a high-efficiency burner with specialized nozzles, while still maintaining stable performance at low firing rates.

Although the PF3100 can support up to 64 pilots and 16 fuel trains, the main advantage for this project was its accuracy. The controller maintains steady burner output and supports the fine gas-flow modulation required for gentle drying. A custom rack-mounted fuel train helps ensure smooth, predictable gas adjustments, so the dryer stays inside the customer’s temperature window.

The customer also wanted better visibility into day-to-day performance. With Modbus communication and data logging, the PF3100 integrates directly with their facility controls, giving operators real-time access to temperature trends and system behavior from their control room. Profire also supported the airflow design to ensure that heat was distributed evenly across the drying chamber, which is essential when processing heat-sensitive botanicals.

Every part of the setup centered on the customer’s process and their strict temperature requirements. The result is a dependable spray drying system that protects product quality, reduces operator workload, and gives them a platform they can continue to expand as production increases.

View Case StudyRecent Projects

The customer specializes in ambient-temperature drying processes that convert juice extracts into shelf-stable powders, while preserving…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

One of our long-term customers faced the serious risk of regulatory penalties at the local, state,…

Our client had a unit with extremely dangerous and violent initial starts. The potential of equipment…

Operational failures experienced during inclement weather conditions coupled with inconsistent performance with the original pilot and…

Our client came to us feeling frustrated with the inefficiency of their Burner Management System. The…

Ensign was experiencing nuisance shutdowns with limited safety I/O. The heater was going down 2-3 times…

The client purchased a second-hand Bryan Boiler with outdated controls and inefficient air to fuel ration…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

An upstream customer required a safer and more reliable burner management solution for their heated process…

It was critical for National Grid to meet compliance standards and create a safe working environment…